Laser cutting with the highest precision.

NEW: We provide laser cutting services for you in the format of 2000 mm x 4000 mm:

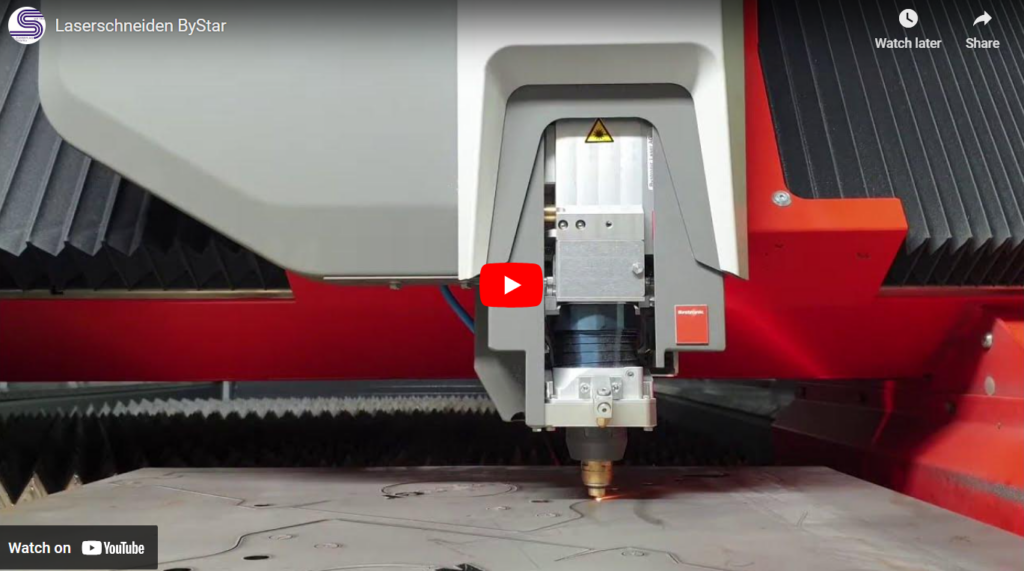

Laser cutting, or laser cuts, operates as follows: Laser cutting is a thermal cutting process used to create precise shapes from sheet metal and various other materials. The laser beam is generated in the laser source and focused by the lens into a very small diameter with high power. This focused laser beam strikes the raw material, causing it to melt.

- Steel: up to 40 mm

- Steel (with BeamShaper option): up to 40 mm

- Stainless steel: up to 40 mm

- Aluminum: up to 40 mm

- Brass: up to 15 mm

- Copper: up to 15 mm

Precise Technology. High-Quality Results. Laser Cutting at Salzgeber AG.

It was just around fifty years ago when lasers began their triumphant journey. Nowadays, lasers are an integral part of our daily lives. They are used in various applications, such as light shows, communications technology, or in every commercially available DVD player. This advanced technology has also rapidly established itself in the industrial sector.

Laser cutting is now one of our core services. The advantage lies in the precision it offers, enabling intricate cuts to be made with ease.

The Formula for Success: Extreme Heat Combined with Precision

In essence, a laser is nothing more than an intensely focused beam. This unique characteristic is fully harnessed in laser cutting. Here’s how it works: First, the laser concentrates on a specific point on the material to be processed. This generates such high temperatures in that area that the workpiece begins to melt. Once the intense beam has entirely pierced the material, laser cutting commences: The laser traverses the workpiece, further cutting through it to create the finest contours. Additionally, a cutting gas is directed through the cutting gap beneath the workpiece. The result is a clean edge and an ultra-thin gap, just slightly wider than the laser beam itself.

As you can see, this precise manufacturing process enables the accomplishment of delicate and intricate cuts through laser cutting. Simultaneously, the workpiece material is optimally utilized, resulting in minimal waste. In principle, all fusible materials can be processed, whether it’s aluminum, copper, stainless steel, or any other structural steel you need to have cut. Consequently, laser cutting is widely regarded as exceptionally efficient and cost-effective in the field of cutting technology.

Already convinced, or still on the fence? Get advice on laser cutting now!

Salzgeber AG has been in existence for nearly eighty years, and we bring this extensive wealth of experience into our daily operations. This is particularly valuable when dealing with relatively new technologies like laser cutting. As a well-established family business, we are eager to support you with all your projects in the fields of plant construction and sheet metal processing. Would you like to get a preview of our daily work? Just visit our YouTube channel, where you’ll find numerous videos showcasing nearly our entire range of services in action. If you’d prefer to visit us in person, that’s not a problem either. Our company address and directions can be found on our website. You’re also welcome to contact us by phone, fax, or email to schedule a consultation. We look forward to meeting you!