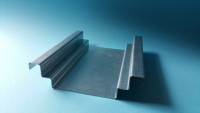

Bending

Precise Bending at the Highest Level with 250 and 80 Tons

- Just a few clicks and the program for this system is ready.

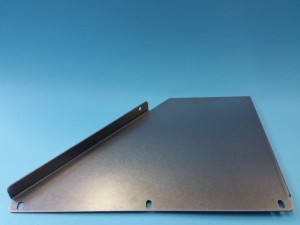

- First-class bending results thanks to pressure reference technology with fully automatic dynamic crowning.

- With the pressing force of 250 t and a bending length of 3000 mm, a variety of bending processes from 0.3 mm to 12 mm are possible.

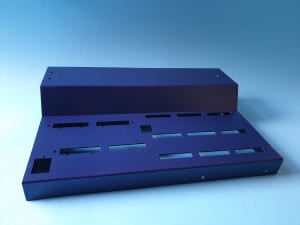

- With our Xpert 80 press brake, we have a pressing force of 80t and a bending length of 1550 mm for optimal process speed for individual and series parts.

- Maximum flexibility for changing order situations: we bend complex small series manually and large series fully automatically

- Autonomous sheet metal bending, with mobile bending cells, the first bending robot in Winterthur.

250 tons of pressing force. 3000 millimeters bending length. This combination allows us to achieve exceptional results when folding.

In general, folding is considered one of the most crucial processes in sheet metal processing. This is because it involves shaping flat material into the desired form, creating a three-dimensional structure. Here’s how folding works: The workpiece is placed in a machine where the punch presses the metal into a die. The sheet metal is bent to a predetermined angle to create a clean edge. Depending on the machine’s programming, a wide variety of shapes can be achieved, making folding an extremely flexible shaping process – allowing you to unleash your creativity without hesitation. Our state-of-the-art pressure reference technology ensures clean, high-quality results during folding. With this technology, the sheet metal is not only bent but also cambered, increasing the metal’s stability!

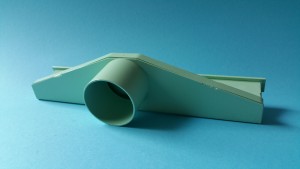

Folding Metal Sheets: Angular Corners or Oval Curves?

In industries like automotive, aviation, chemistry, or construction, bent materials are integral to various applications. Therefore, it’s essential to give the necessary individual parts the correct shape during folding to fulfill their purpose.

Whether you need square or round workpieces, it’s not an issue. Thanks to our precise bending technology, even unusual shapes can be easily created. The best part is that it only takes a few clicks to program the machine for bending. All you need to do is provide us with the desired dimensions, including the corresponding angles or radii. If you’d like to see it in action, we have videos on our website demonstrating our machines in the folding process. A quick look is worthwhile!

Interested? Inquire Now!

Are you currently working on a new project or have already developed your initial plan? We’d be delighted to provide you with guidance on sheet metal processing. With our years of experience, you can count on a competent partner who will offer comprehensive support. In addition to folding, our range of services includes other activities like laser cutting, water jet cutting, welding work, and various cutting processes. Our recommendation: Get in touch with us! You can find our contact details on our website, including fax and telephone numbers, email address, and our physical address with directions. We eagerly await your call, inquiry, or visit!