Machinery

We work with different machines. Click on the names to find out more.

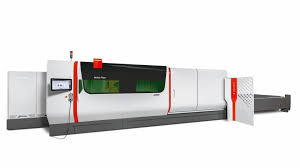

Laser cutting system

Laser cutting with the highest dynamics.

Laser cutting is a thermal process used to cut precise shapes from sheet metal and other materials.

The laser beam is generated in the laser source and focused through a lens to a very small, high-powered diameter.

This focused laser beam is directed at the raw material, causing it to melt.

The modifications here help to make the text a bit more clear and concise.

We provide laser cutting services for you in the format of 1500 mm x 3000 mm:

- Structural steel St37 and St52 / 20 mm – up to 6 mm with N², from 8 mm with O²

- Stainless steel / up to 20 mm with N²

- Aluminum / up to 15 mm

- Brass / up to 8 mm

- Copper / up to 8 mm

Technical data:

Material dimensions: 1500 x 3000 mm Material thickness: 0.1-20 mm Position deviation: ± 0.05 mm Cutting tolerance: ± 0.1 mm Suitable materials: aluminum, stainless steel, steel, copper, brass, titanium

Water jet machine

Bystronic Byjet Pro 3015 with 3600bar

- 2 cutting heads

- 2 drilling jigs for multi-layer materials

- Table size: 3000 x 1500

Guillotine Shears

Vimercati

- Steel up to 10 mm x 3000 mm

- Stainless steel up to 6 mm x 3000 mm

- Aluminum up to 12 mm x 3000 mm

Press brakes

Xpert 250 with highest performance

Achieve excellent bending results thanks to pressure reference technology with fully automatic dynamic crowning.

- CNC press brake

- Bending length of 3100 mm

- Energy Save

Bystronic Xpert Pro 250

Xpert 80 at maximum speed

With our new press brake, we possess 80 tons of pressing force and a bending length of 1550 mm, ensuring an optimal processing speed for both individual parts and series production.

- CNC press brake

- Bending length of 1550 mm

- Energy Save

Round machines

Schröder / FASTI

- Usable length: 1040 mm

- Steel: Up to 4 mm x 1000

- Chrome steel: Up to 3 mm x 1000

- Aluminum: Up to 5 mm x 1000

Welding

REHM INVERTIG.PRO digital – direct/alternating current TIG welding machine

REHM Synergic.Pro² compact series – step-switched MIG-MAG welding machine for spot welding

Stud welding

Arc welding

Oxy-fuel welding

Hard and soft soldering

Boschert notching machine

6 x 250 mm 90 Grad

Deburring, Rounding or Finish Grinding

The deburring machine is a compact, dry-working machine used for deburring, rounding, and/or finish grinding various materials.

Setting a new standard in deburring, edge rounding, and finish grinding technology for a wide range of materials, this compact machine features a newly developed rotary brush head.

Trovalizing machine

1000×500

Saws

Up to a diameter of 160 mm 30 degrees

Circular Scissors

Fe 2mm diameter 1200mm

Sink Machines

3 Types

Lapping Machine

Up to diameter 180 mm

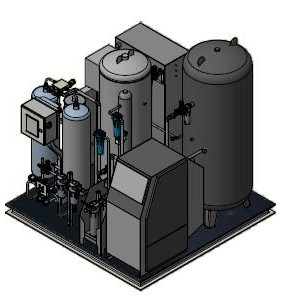

Nitrogen generator

With our nitrogen generator PSAL-25SN, we can independently produce nitrogen with a purity of up to 99.999% for our laser cutting system.

The nitrogen generators produce nitrogen from compressed air. The air is initially passed through pre-filtration to remove contaminants such as moisture, oil vapors, particulates, and hydrocarbons. The cleaned compressed air stream is then directed into the adsorption containers. Oxygen and carbon dioxide molecules are removed, and the pressure dew point is simultaneously lowered. This process creates dry and pure nitrogen gas. The produced nitrogen is subsequently pumped into a storage tank and compressed to a maximum pressure of 300 bar.