Surface Treatment

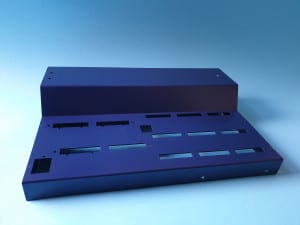

Surface treatment: Thanks to our partner companies, we can provide various surface treatment options for you, including:

- Powder coating

- Wet painting

- KTL coating

- Galvanic surface treatments

- Teflon coating

- Labeling and printing

- Pickling and passivating chrome steel or aluminum

- Sand and glass bead blasting over 500 mm

- Laser engraving

- Anodizing

- Browning

- Various special coatings

Labeling/printing

In screen printing, a tightly woven textile fabric is employed. Stencils are used to cover all areas where the design does not require color. The fabric is then positioned on the surface to be printed, and paint is pushed over the mesh using a rubber squeegee. This process transfers the printed design onto the surface, making screen printing also referred to as a through-printing process.

Cathodic dip painting KTL: process and advantages

The KTL process relies on electrophoresis: the workpieces, which carry a negative charge, interact with the positively charged paint particles within the immersion bath. This results in the uniform application of the desired paint thickness, even within the smallest crevices, corners, and capillary openings. The paint is applied at approximately 200°C.

Surface treatment is a fundamental component of surface technology, which encompasses all the processes used to modify surface properties. Examples include powder coating, wet painting, KTL coating, galvanic surface treatments, Teflon coating, labeling/printing, pickling/passivation of chrome steel or aluminum, sand and glass bead blasting for items over 500 mm in size, laser engraving, anodizing, burnishing, and more.

Goals

- Achieve optimal surface finishing for all metals.

- Use insulating properties to prevent electrical attraction of the workpieces.

- Provide high impact resistance and optimal corrosion protection.

- Promote ecological practices with economical paint consumption.

- Serve various industries, including automotive, machinery, and high-tech applications.

Feel free to contact us by phone or email to send your inquiry, and we will respond promptly!